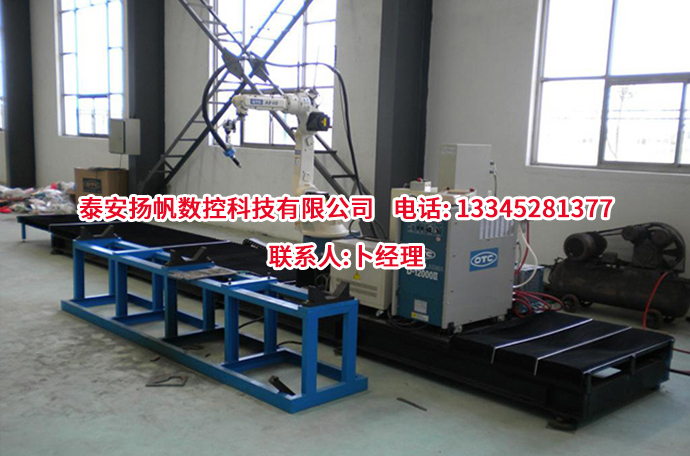

自動(dòng)焊接設(shè)備的操作以及維護(hù)

來源:http://meangen.com/ 發(fā)布時(shí)間:2022-09-29 瀏覽次數(shù):0

好的設(shè)備必須好的保養(yǎng),還請(qǐng)朋友們?cè)诓捎弥卸喽嗟牧粢鈱?duì)其的保養(yǎng),只有這種才可以延長(zhǎng)壽命,為高質(zhì)量的焊接奠定基礎(chǔ)。下面山東自動(dòng)焊接設(shè)備廠家為您講講自動(dòng)焊接設(shè)備的操作以及維護(hù)內(nèi)容。

Good equipment must be well maintained. Please pay more attention to its maintenance when using it. Only this can prolong its life and lay a foundation for high-quality welding. Next, Shandong automatic welding equipment manufacturer will tell you about the safe operation and maintenance of automatic welding equipment.

自動(dòng)焊接設(shè)備的操作

Safe operation of automatic welding equipment

1.工作前仔細(xì)檢查工具,設(shè)備是不是完整,焊機(jī)接地是不是靠譜地接地,焊機(jī)的修理應(yīng)由電器保養(yǎng)人員做好,別的人員不能拆修。

1. Before work, carefully check whether the tools and equipment are complete, and whether the welding machine is grounded reliably. The repair of the welding machine should be done by the electrical maintenance personnel, and other personnel should not dismantle and repair it.

2.工作前要仔細(xì)的檢查工作環(huán)境,確定為正常方可開始工作,工作前配戴好勞動(dòng)防護(hù)用品。

2. Before work, carefully check the working environment and ensure that it is normal and safe before starting work. Wear labor protection articles before work.

3.高空焊接時(shí)要佩戴帶,帶記掛時(shí),一定要避開焊接部位和地線部位,以防焊接時(shí)把帶燙斷。

3. The safety belt shall be worn when welding at heights. When the safety belt is hung, the welding part and ground wire must be avoided to prevent the safety belt from burning off during welding.

4.接地線要牢靠,禁止用腳手架、鋼絲纜繩、機(jī)床等作接地線。通常標(biāo)準(zhǔn)是焊接點(diǎn)的就近點(diǎn),帶電設(shè)備放置地線一定要當(dāng)心,不能把設(shè)備導(dǎo)線和地線連接,以防燒毀設(shè)備或發(fā)生火災(zāi)。

4. The grounding wire shall be secure and safe. Scaffolds, wire ropes, machine tools, etc. are not allowed to be used as grounding wires. Generally, the standard is the nearest point of the welding point. Be careful when placing the ground wire of the live equipment. Do not connect the equipment wire with the ground wire to avoid burning the equipment or causing a fire.

自動(dòng)焊接機(jī)如何維修保養(yǎng)

How to repair and maintain the automatic welding machine

1.再開始開機(jī)前行設(shè)備查驗(yàn),包含外型檢查和內(nèi)部查驗(yàn)。外部便是看是否有損壞或零件問題,如果有及時(shí)檢修解決,內(nèi)部查驗(yàn)包含電機(jī)、電路、控制裝置等的檢測(cè)。

1. Before starting the machine again, carry out equipment inspection, including appearance inspection and internal inspection. The external inspection is to check whether there is any damage or part problem. If it is timely repaired and solved, the internal inspection includes the detection of motor, circuit, control device, etc.

2.企業(yè)須具備合格的車間、機(jī)器、設(shè)備,如倉(cāng)庫(kù)、熱處理設(shè)備、焊接設(shè)備和測(cè)試設(shè)備等。讓專門的人員做好使用解決。

2. The enterprise must have qualified workshops, machines and equipment, such as warehouses, heat treatment equipment, welding equipment and testing equipment. Let special personnel do a good job of using and solving.

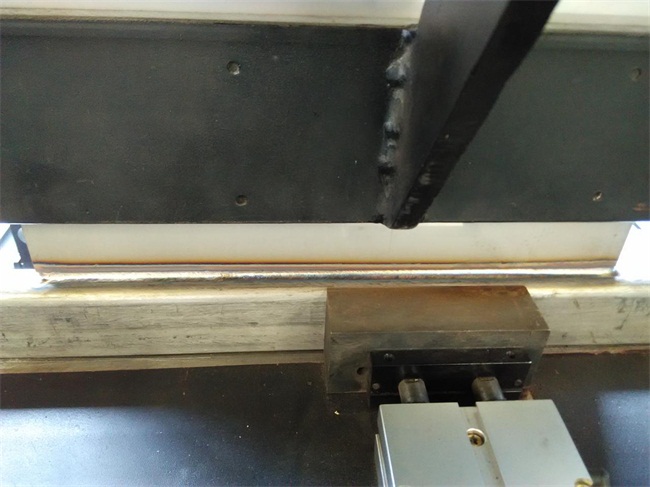

3.當(dāng)焊接導(dǎo)熱系數(shù)較高的金屬如銅、鋁及其合金時(shí),應(yīng)挑選熱輸入強(qiáng)度大、具備較高焊透能力的焊接方法,以便被焊金屬在短的時(shí)長(zhǎng)內(nèi)做到熔化狀態(tài),并使工件變形小。

3. When welding metals with high thermal conductivity, such as copper, aluminum and their alloys, the welding method with high heat input strength and high penetration capacity shall be selected, so that the metal to be welded can be melted in a short time and the workpiece deformation is small.

此外在接拆電焊機(jī)電源線或電焊機(jī)發(fā)生故障時(shí),應(yīng)會(huì)同電工一起做好修理,嚴(yán)防觸電事故,為重。更多相關(guān)內(nèi)容就來我們網(wǎng)站http://meangen.com咨詢吧!

In addition, when connecting or removing the power line of the electric welding machine or the electric welding machine fails, repair it together with the electrician to prevent electric shock accidents. Safety is the most important. More relevant content will come to our website http://meangen.com Consult!