焊接專機(jī)使用時要考察到五方面

來源:http://meangen.com/ 發(fā)布時間:2022-10-13 瀏覽次數(shù):0

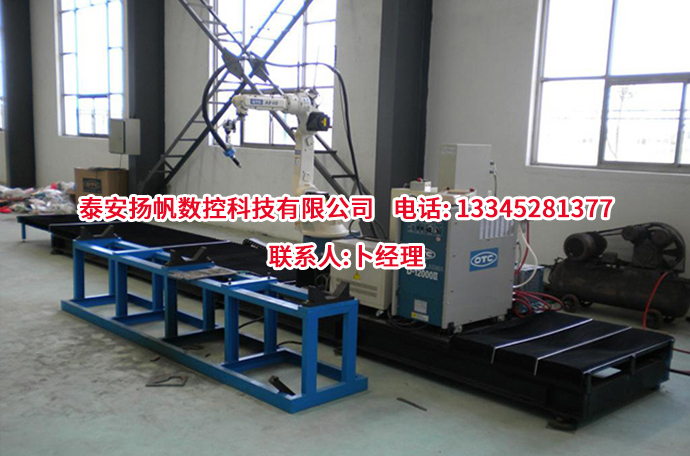

焊接專機(jī)在使用時要及時進(jìn)行調(diào)節(jié),保證其在焊接過程中順利進(jìn)行,各種焊接設(shè)備的性能、穩(wěn)定性和可靠性直接影響焊接質(zhì)量。下面來給大家介紹下山東焊接專機(jī)使用時要考察到五方面的具體內(nèi)容。

The special welding machine shall be adjusted in time when it is used to ensure the smooth welding process. The performance, stability and reliability of various welding equipment directly affect the welding quality. Now let's introduce the specific contents of five aspects to be investigated when using the special welding plane in Shandong.

一、工件的適用原則:根據(jù)施工機(jī)械不同布置部位的形狀差別很大,對焊接式變位機(jī)的要求也不同。所以,在使用時應(yīng)根據(jù)焊接布置件的布置特點(diǎn)和焊接要求,選擇合適的焊接專機(jī)。

1、 Applicable principle of workpieces: the shapes of different positions of construction machinery vary greatly, and the requirements for welding positioner are also different. Therefore, suitable special welding machine shall be selected according to the layout characteristics of welding layout parts and welding requirements.

二、如果在方便焊接的原則下,可以根據(jù)手工焊接操作的狀態(tài),選用的焊接式變位機(jī)應(yīng)能將焊工的任何焊縫轉(zhuǎn)移到平焊或船焊位置,防止立焊和仰焊,保證焊接質(zhì)量。

2、 Under the principle of convenient welding, according to the state of manual welding operation, the selected welding positioner shall be able to transfer any welding seam of the welder to the position of flat welding or ship welding, prevent vertical welding and overhead welding, and ensure the welding quality.

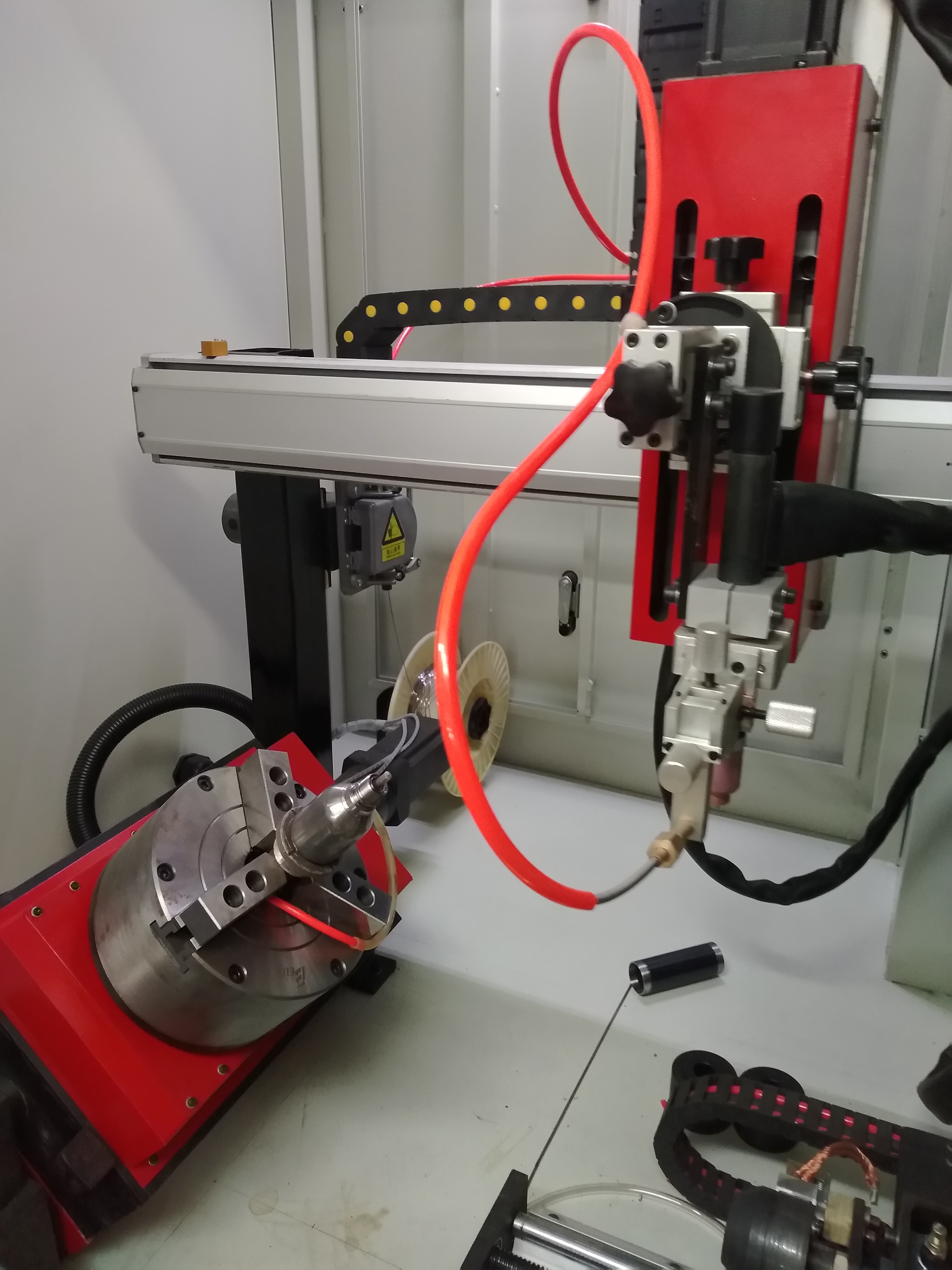

三、一般來說環(huán)縫焊接選用變位機(jī)時,應(yīng)根據(jù)焊件的坡口考慮反向旋轉(zhuǎn)速度。速度應(yīng)保證在定位器轉(zhuǎn)速調(diào)節(jié)范圍內(nèi),盡量保持勻速進(jìn)行操作,這樣才有利于焊接過程的進(jìn)行。并滿足工作平臺在運(yùn)行中的穩(wěn)定性要求。

3、 Generally speaking, when the positioner is selected for circumferential welding, the reverse rotation speed shall be considered according to the groove of the weldment. The speed shall be within the range of the positioner speed adjustment, and the operation shall be carried out at a constant speed as far as possible, which is conducive to the welding process. And meet the stability requirements of the working platform in operation.

四、如果焊接專機(jī)整個焊件在外輪廓上的尺寸較大,則需要考慮工作臺的傾斜,或傾斜角度是否能滿足焊件的焊接位置。當(dāng)斜角與焊件接觸時,選擇工作臺時,工作臺與地面的間隙應(yīng)較大,保證整個焊接的加工要求。

4、 If the size of the whole weldment on the outer contour of the welding machine is large, it is necessary to consider whether the tilt of the workbench or the tilt angle can meet the welding position of the weldment. When the bevel is in contact with the weldment, when the workbench is selected, the gap between the workbench and the ground shall be large to ensure the processing requirements of the whole welding.

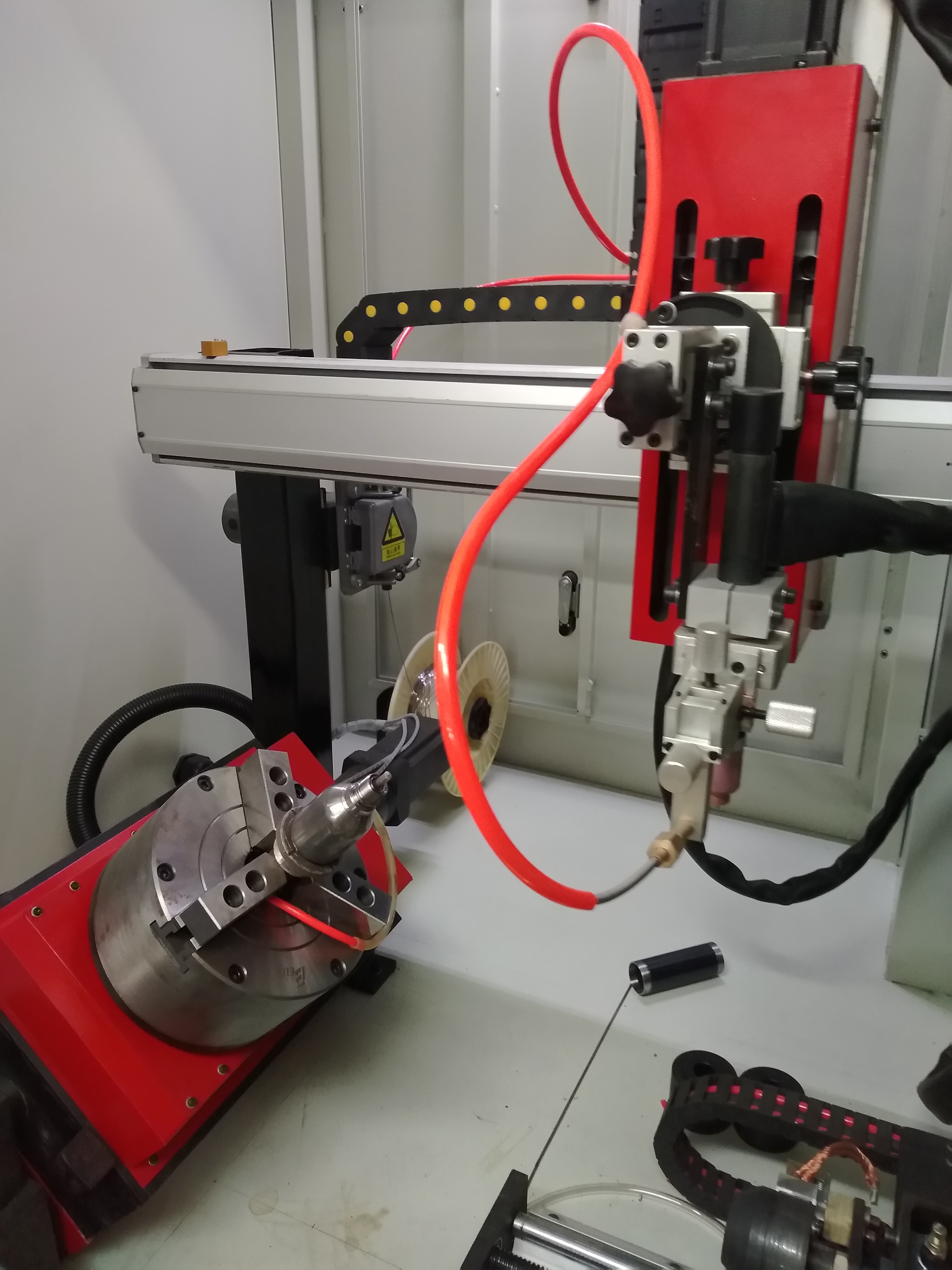

五、本著操作方便、可靠、開啟、操作高度低、布置緊湊的原則,選用焊接式變位機(jī),方便工人操作和放置變位機(jī)。如果變位機(jī)的焊接作業(yè)高度較高,工人可以通過焊盤高度進(jìn)行焊接,也可以通過組裝液壓升降平臺來調(diào)整高度位置。

5、 Based on the principles of convenient operation, safety and reliability, opening, low operating height and compact layout, welding positioner is selected to facilitate workers to operate and place the positioner. If the welding operation height of the positioner is high, workers can weld by the height of the pad, or adjust the height position by assembling the hydraulic lifting platform.

以上就是焊接專機(jī)使用時應(yīng)該考慮到的這些內(nèi)容,在選擇使用時需要明確好工件加工的質(zhì)量等因素,要保證后期的加工過程的順利進(jìn)行,也要注意好整體的焊接效果。關(guān)注我們網(wǎng)站http://meangen.com,咨詢到更多事項(xiàng)!

These are the contents that should be taken into account when using the special welding machine. When selecting and using the special welding machine, it is necessary to determine the factors such as the quality of the workpiece processing. To ensure the smooth process of the later processing, it is also necessary to pay attention to the overall welding effect. Follow our website http://meangen.com , asked for more!

上一篇:在使用焊接操作機(jī)時應(yīng)留意什么事項(xiàng)

下一篇:自動焊接設(shè)備使用中易產(chǎn)生的四個問題