自動(dòng)焊接設(shè)備在工業(yè)生產(chǎn)中的作用

來源:http://meangen.com/ 發(fā)布時(shí)間:2023-10-24 瀏覽次數(shù):0

汽車制造

Automobile manufacturing

自動(dòng)焊接設(shè)備在汽車制造中的應(yīng)用占據(jù)了重要的位置。汽車生產(chǎn)線上的許多焊接任務(wù)都需要高速、高精度的焊接,傳統(tǒng)手工焊接工作難以滿足這些要求,而自動(dòng)焊接設(shè)備可以自行判斷焊接位置和弧長,根據(jù)焊接任務(wù)參數(shù)進(jìn)行高精度的控制和調(diào)整,能夠提高生產(chǎn)效率和生產(chǎn)質(zhì)量。

The application of automatic welding equipment in automotive manufacturing occupies an important position. Many welding tasks on automotive production lines require high-speed and high-precision welding, which traditional manual welding work cannot meet. However, automatic welding equipment can independently determine the welding position and arc length, and perform high-precision control and adjustment based on welding task parameters, which can improve production efficiency and quality.

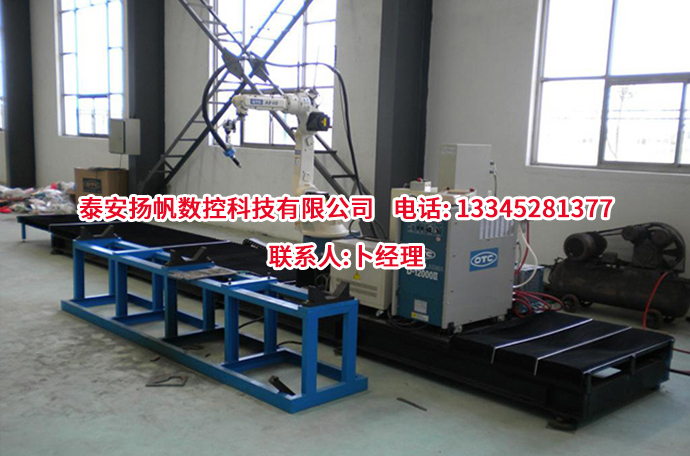

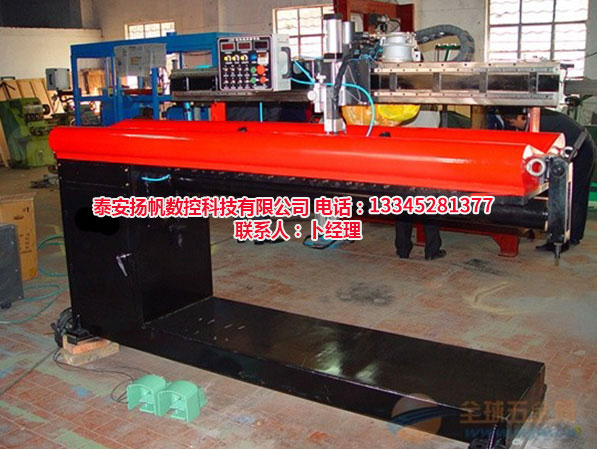

自動(dòng)焊接設(shè)備

Automatic welding equipment

航空航天

Aerospace

航空航天領(lǐng)域的生產(chǎn)制造對焊接的要求尤為高,要求焊接點(diǎn)精度高、焊縫密度大、焊接工藝穩(wěn)定等。自動(dòng)焊接設(shè)備在航空航天制造中的應(yīng)用得到了廣泛的應(yīng)用,如制造國產(chǎn)大型噴氣客機(jī)中的機(jī)身焊接、火箭發(fā)動(dòng)機(jī)外殼焊接等都有使用到自動(dòng)焊接設(shè)備來完成。

The production and manufacturing in the aerospace field have particularly high requirements for welding, such as high precision of welding points, high weld density, and stable welding processes. The application of automatic welding equipment in aerospace manufacturing has been widely applied, such as the welding of the fuselage of domestic large jet aircraft and the welding of rocket engine shells, which are all completed using automatic welding equipment.

建筑工程

construction engineering

自動(dòng)焊接設(shè)備在建筑工程中的應(yīng)用范圍也很廣泛,如鋼結(jié)構(gòu)構(gòu)件的連接焊接、建筑鋼管的連接焊接、建筑物外墻的制作和安裝等。傳統(tǒng)手工焊接在這些領(lǐng)域中受制于焊接工藝、工作環(huán)境等因素,而自動(dòng)焊接設(shè)備可以有效地解決這些問題,提高生產(chǎn)效率和質(zhì)量,降低了生產(chǎn)成本。

The application range of automatic welding equipment in construction engineering is also very wide, such as the connection welding of steel structural components, the connection welding of building steel pipes, and the production and installation of building exterior walls. Traditional manual welding is constrained by factors such as welding process and working environment in these fields, and automatic welding equipment can effectively solve these problems, improve production efficiency and quality, and reduce production costs.

電子制造

Electronic manufacturing

電子制造行業(yè)需要進(jìn)行精細(xì)的焊接工作,手工焊接難以滿足高精度焊接的需求。自動(dòng)焊接設(shè)備可以自動(dòng)完成電子元器件的連接、線路板的焊接等任務(wù),可以高速、、準(zhǔn)確地完成各種復(fù)雜的焊接任務(wù)。

The electronic manufacturing industry requires precise welding work, and manual welding is difficult to meet the needs of high-precision welding. Automatic welding equipment can automatically complete tasks such as connecting electronic components and welding circuit boards, and can complete various complex welding tasks quickly, efficiently, and accurately.

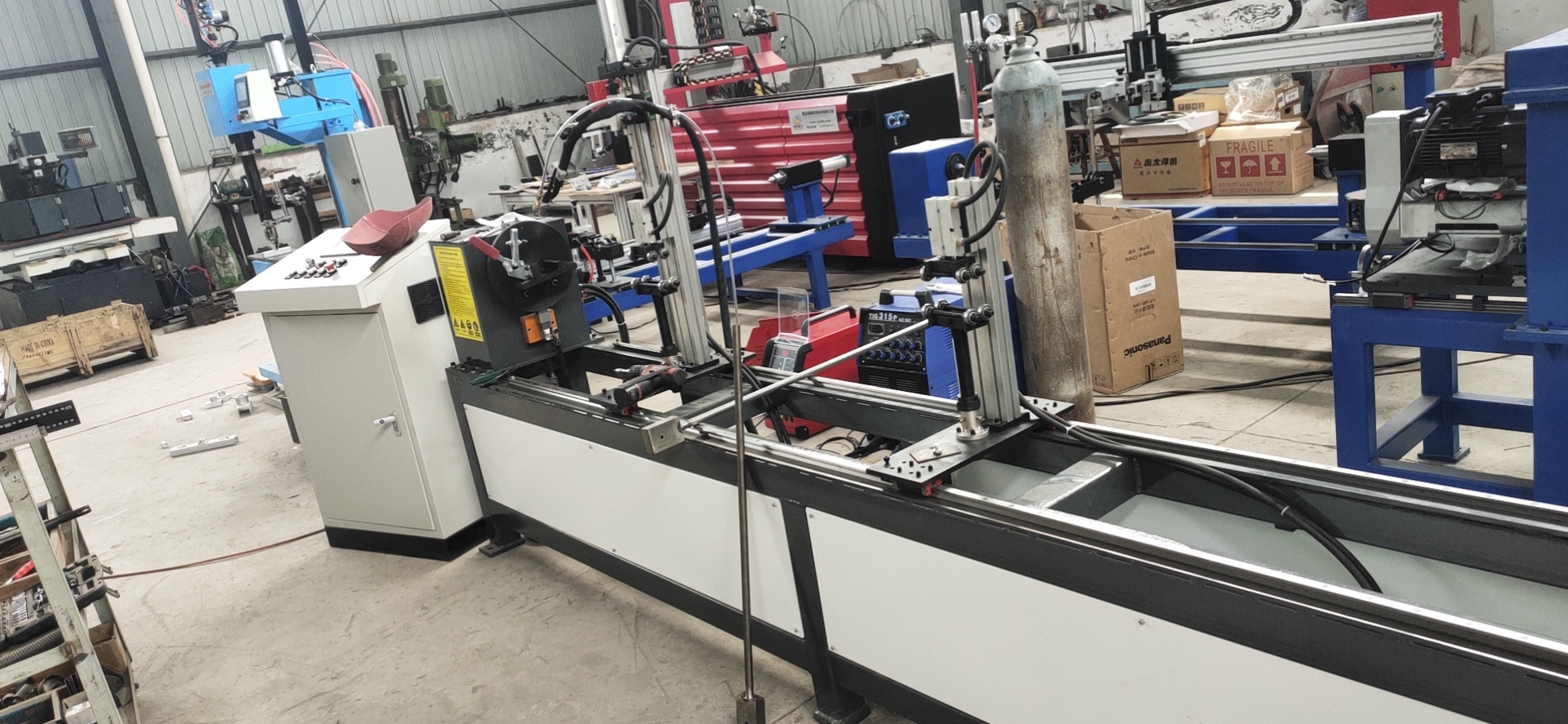

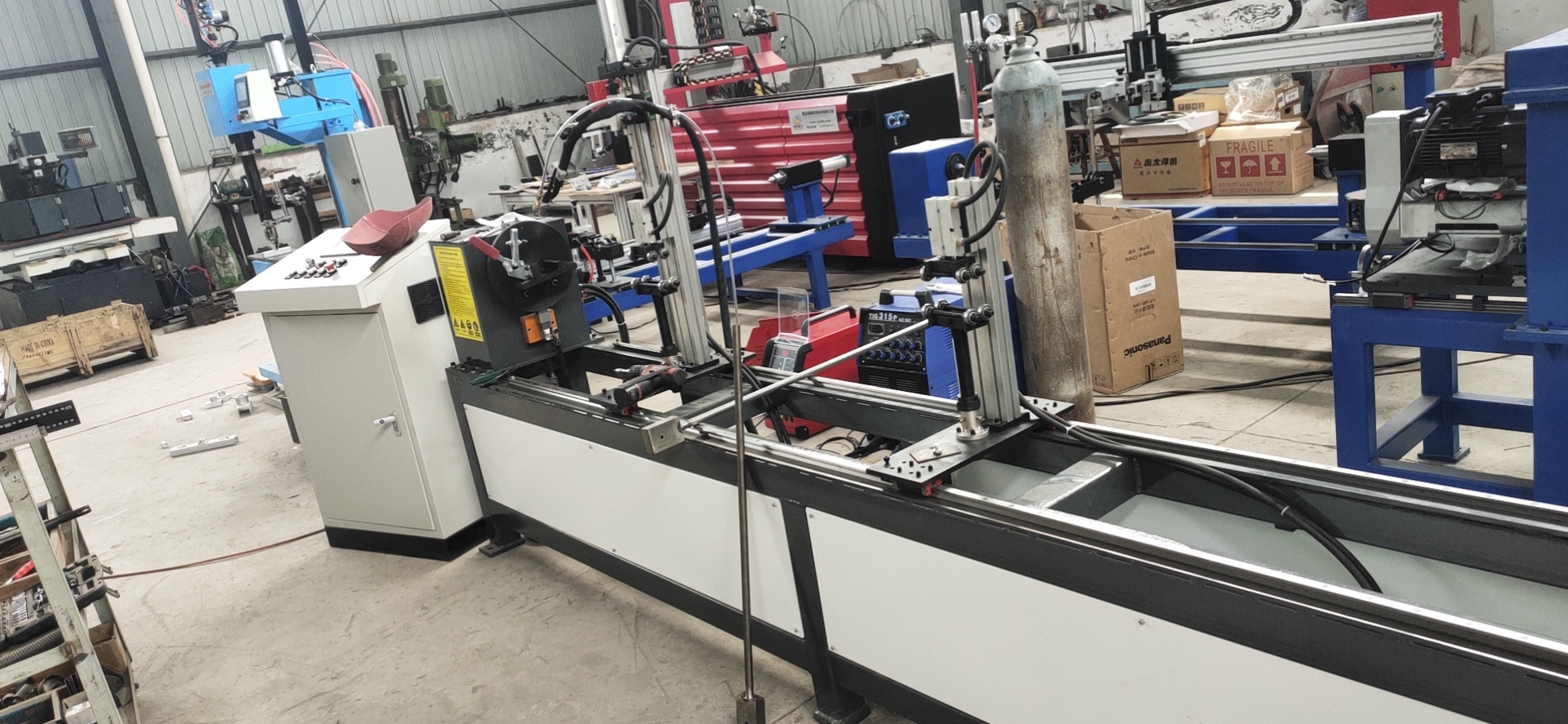

管道工程

Pipeline engineering

管道焊接是管道工程中重要的工序之一,由于管道的材料多樣化、尺寸精度高、形狀復(fù)雜等原因,傳統(tǒng)手工焊接難以勝任這項(xiàng)任務(wù)。自動(dòng)焊接設(shè)備可以根據(jù)管道的尺寸、形狀、材料等特性,對焊接弧大幅度調(diào)整、實(shí)現(xiàn)焊接自動(dòng)化。

Pipeline welding is one of the important processes in pipeline engineering. Due to the diverse materials, high dimensional accuracy, and complex shape of pipelines, traditional manual welding is difficult to perform this task. Automatic welding equipment can greatly adjust the welding arc and achieve welding automation based on the size, shape, material and other characteristics of the pipeline.

本文由山東自動(dòng)焊接設(shè)備提供技術(shù)支持,更多的詳細(xì)精彩內(nèi)容請點(diǎn)擊我們的網(wǎng)站http://meangen.com,我們將會全心全意為您提供滿意的服務(wù)

This article is supported by Shandong Automatic Welding Equipment. For more detailed and exciting content, please click on our website http://meangen.com We will wholeheartedly provide you with satisfactory service