自動焊接設(shè)備搭配焊接變位機(jī)進(jìn)行協(xié)調(diào)使用

來源:http://meangen.com/ 發(fā)布時間:2022-06-21 瀏覽次數(shù):0

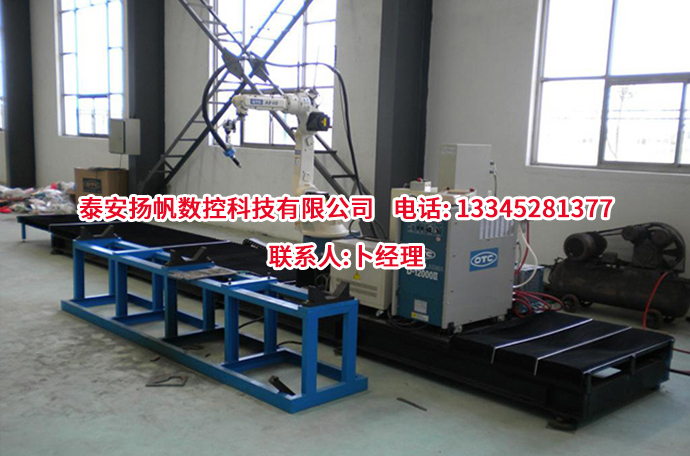

事實上,自動焊接設(shè)備可以穩(wěn)定焊接質(zhì)量,提高焊接市場的焊接效率。面對較為復(fù)雜的工件,自動焊接設(shè)備的靈活性有限,通常與焊接變位機(jī)配合使用。通過兩者的協(xié)調(diào)運(yùn)動,實現(xiàn)柔性焊接,下面我們來了解一下相關(guān)內(nèi)容。

In fact, automatic welding equipment can stabilize the welding quality and improve the welding efficiency of the welding market. In the face of complex workpiece, the flexibility of automatic welding equipment is limited, and it is usually used together with welding positioner. Through the coordinated movement of the two, flexible welding can be realized. Let's learn about the relevant contents below.

山東自動焊接設(shè)備采用示教復(fù)制的方式。操作人員根據(jù)實際任務(wù)引導(dǎo)機(jī)械臂,逐步操作。自動焊接設(shè)備自動記憶位置、姿態(tài)、運(yùn)動參數(shù)、焊接參數(shù)等,并自動生成程序,連續(xù)執(zhí)行所有操作。完成示教后,只需發(fā)出啟動命令即可實現(xiàn)自動化工作。

Shandong automatic welding equipment adopts teaching replication. The operator guides the manipulator to operate step by step according to the actual task. Automatic welding equipment automatically memorizes position, posture, motion parameters, welding parameters, etc., and automatically generates programs to continuously perform all operations. After the teaching is completed, the automatic work can be realized by issuing the start command.

焊接變位機(jī)作為一種常見的焊接輔助設(shè)備,可根據(jù)軸數(shù)實現(xiàn)360°或120°翻轉(zhuǎn),并根據(jù)不同的負(fù)載能力,滿足不同領(lǐng)域工件的承載,確保穩(wěn)定轉(zhuǎn)動和工作在軸承范圍內(nèi)。工作臺設(shè)有固定孔,可對工件進(jìn)行固定、旋轉(zhuǎn)、翻轉(zhuǎn),提高穩(wěn)定性。

As a common welding auxiliary equipment, the welding positioner can turn 360 ° or 120 ° according to the number of shafts, and meet the load of workpieces in different fields according to different load capacities, so as to ensure stable rotation and work within the bearing range. The worktable is provided with a fixing hole, which can fix, rotate and flip the workpiece to improve the stability.

同步和協(xié)調(diào)的運(yùn)動。同步配合是指自動焊接設(shè)備工作時,焊接變位機(jī)按指令同步移動,使待焊空間曲線的焊縫置于便于焊接的位置。對精度和運(yùn)動精度的要求比較高。

Synchronized and coordinated movement. Synchronous fit means that when the automatic welding equipment is working, the welding positioner moves synchronously according to the instructions, so that the weld of the space curve to be welded is placed at a position convenient for welding. The requirements for accuracy and motion accuracy are relatively high.

異步協(xié)調(diào)運(yùn)動。異步配合對焊接變位機(jī)的精度要求較高。自動焊接設(shè)備進(jìn)行焊接工作時,焊接變位機(jī)不動。自動焊接設(shè)備完成工作后,根據(jù)指令將焊接變位機(jī)調(diào)整到其他位置,為下一次做準(zhǔn)備。如此異步的焊接任務(wù)知道所有焊縫都已焊接。

Asynchronous coordinated motion. Asynchronous matching requires high precision of welding positioner. When the automatic welding equipment performs welding, the welding positioner does not move. After the automatic welding equipment completes the work, adjust the welding positioner to other positions according to the instructions to prepare for the next time. Such an asynchronous welding task knows that all welds have been welded.

焊接變位機(jī)作為山東自動焊接設(shè)備的輔助設(shè)備,已成為不可缺少的設(shè)備。焊接變位機(jī)幫助焊接機(jī)器人實現(xiàn)穩(wěn)定焊接,提高焊接的自動化程度,有效提高自動焊接設(shè)備的生產(chǎn)速度,為企業(yè)帶來效益更大的利益。

As the auxiliary equipment of Shandong automatic welding equipment, welding positioner has become an indispensable equipment. Welding positioner helps welding robot realize stable welding, improve the automation of welding, effectively improve the production speed of automatic welding equipment, and bring greater benefits to enterprises.

以上就是今天為大家分享的關(guān)于問題的相關(guān)內(nèi)容,希望對大家能有所幫助,想要了解更多內(nèi)容可以電話聯(lián)系我們或者關(guān)注我們的網(wǎng)站http://meangen.com。

The above is the relevant content about the problem shared for you today. I hope it can help you. If you want to know more, you can contact us by phone or follow our website http://meangen.com 。