操作自動焊接設(shè)備進(jìn)行焊接中的留意事項

來源:http://meangen.com/ 發(fā)布時間:2022-10-29 瀏覽次數(shù):0

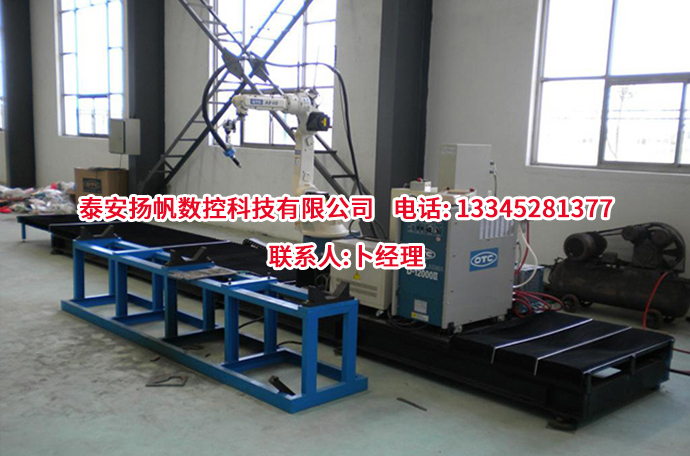

企業(yè)為了自動化生產(chǎn),加快轉(zhuǎn)型升級,開始使用自動焊接設(shè)備來代替?zhèn)鹘y(tǒng)焊接,自動焊接設(shè)備可以提高焊接效率,對任意復(fù)雜工件實現(xiàn)精確焊接,穩(wěn)定焊接質(zhì)量,滿足了企業(yè)的市場競爭需求,企業(yè)在操作自動焊接設(shè)備進(jìn)行焊接中,需要注意哪些事項,山東自動焊接設(shè)備廠家?guī)私狻?/div>

In order to automate production and accelerate transformation and upgrading, enterprises began to use automatic welding equipment to replace traditional welding. Automatic welding equipment can improve welding efficiency, achieve accurate welding for any complex workpiece, stabilize welding quality, and meet the market competition needs of enterprises. What matters should be paid attention to in the operation of automatic welding equipment for welding? Shandong automatic welding equipment manufacturer will show you.

企業(yè)進(jìn)行焊接工作的環(huán)境一般都是在生產(chǎn)車間里,在生產(chǎn)線中會有其他大型設(shè)備,在自動焊接設(shè)備的周圍盡量遠(yuǎn)離大型振動設(shè)備,以免影響到焊接精確度,清理自動焊接設(shè)備周圍的油污雜質(zhì),在所能達(dá)到的焊接范圍處加裝圍欄,以防在工作過程中有人員進(jìn)入。

The environment for enterprises to carry out welding work is generally in the production workshop. There will be other large equipment in the production line. The area around the automatic welding equipment should be as far away from the large vibration equipment as possible to avoid affecting the welding accuracy. The oil and impurities around the automatic welding equipment should be cleaned up, and the welding range should be equipped with a fence to prevent personnel from entering during the work process.

在進(jìn)入量產(chǎn)前,需要對自動焊接設(shè)備進(jìn)行調(diào)試工作,操作人員根據(jù)焊縫的質(zhì)量來對焊接參數(shù)進(jìn)行調(diào)整,這樣經(jīng)過2-3次細(xì)微調(diào)整后,自動焊接設(shè)備的焊接質(zhì)量達(dá)到要求,可以投入量產(chǎn)。

Before mass production, the automatic welding equipment needs to be debugged. The operator adjusts the welding parameters according to the quality of the weld. After 2-3 minor adjustments, the welding quality of the automatic welding equipment meets the requirements and can be put into mass production.

焊接過程中人為因素有時候會出現(xiàn)誤操作,在選擇焊接參數(shù)或者進(jìn)行示教操作時出現(xiàn)錯誤,在剛開始進(jìn)行操作時選用熟練地操作人員,定期對操作人員以及技術(shù)人員進(jìn)行培訓(xùn),提高自動焊接的相關(guān)技能。

In the process of welding, human factors sometimes cause misoperation, and errors occur when selecting welding parameters or conducting teaching operations. Skilled operators are selected at the beginning of the operation, and operators and technicians are trained regularly to improve the relevant skills of automatic welding.

人員在進(jìn)入工作之前,佩戴好防護(hù)護(hù)具,在開始工作后需要手持示教器站在焊接范圍之外,通過示教器進(jìn)行操作,當(dāng)自動焊接設(shè)備出現(xiàn)報警信號時,需要按下急停按鈕,停止焊接工作,對設(shè)備進(jìn)行檢查以及調(diào)整。

Before entering the work, the personnel shall wear protective equipment. After starting the work, they need to stand outside the welding range with a hand-held teaching device and operate through the teaching device. When the automatic welding equipment has an alarm signal, they need to press the emergency stop button to stop the welding work and check and adjust the equipment.

以上就是自動焊接設(shè)備在操作過程中需要注意的事項,自動焊接設(shè)備如果操作得當(dāng),可以提高焊接效率,穩(wěn)定焊接質(zhì)量,提高產(chǎn)品的市場競爭力。當(dāng)然為了著想,您在操作前后一定要對設(shè)備進(jìn)行相應(yīng)的檢查,關(guān)注我們http://meangen.com帶您了解更多使用事項!

The above are the matters needing attention during the operation of automatic welding equipment. If the automatic welding equipment is properly operated, it can improve the welding efficiency, stabilize the welding quality and improve the market competitiveness of products. Of course, for the sake of safety, you must check the equipment before and after operation, and pay attention to us http://meangen.com Learn more about using!